- 08

- Aug

Kedu ka gia ugboro abụọ nke induction kpo oku ọkụ na-emenyụ ahịrị mmepụta si arụ ọrụ?

Kedu ka ihe eji eme ugboro abụọ induction kpo oku ọkụ quenching mmepụta akara ọrụ?

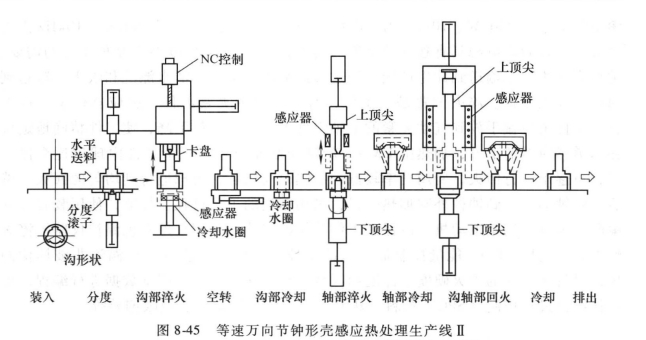

Ụlọ ọrụ American TOCC0 emebere ma rụpụta ọkụ ọkụ induction ugboro abụọ na-emenyụ na nkwụsị mmepụta maka ngwa n’ime ime na ngwa anyanwụ maka ụlọ ọrụ mgbasa ozi. Nke a mmepụta ahịrị mejupụtara abụọ 100kW, 10kHz etiti ugboro siri ike-ala ike onunu, otu maka esịtidem gia na nke ọzọ maka anyanwụ gia; Igwe ọkụ dị elu bụ 200kW, 450kHz.

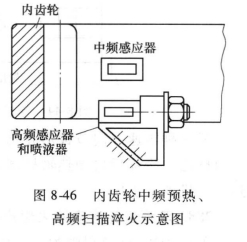

Ngwunye na iwe ọkụ nke ime gia A na-ebutu gia dị n’ime nke ahịrị mmepụta a otu ibe n’otu oge ma jiri cylinder abụọ na-emegide ya na-arụ ọrụ. Mgbe workpiece bụ na No. 1 loading ọnọdụ, a idi nso mgba ọkụ na-eme ka pneumatic reciprocating mkpanaka ịkwanye workpiece na quenching ọdụ. Ebe a nwere servo na-agbanwe ngwa ngwa na nkwado nyocha kwụ ọtọ, ngwa ahụ rutere ebe a na-emenyụ ọkụ, na nke ọzọ Mgbanwe dị nso na-arụ ọrụ, yabụ nyocha kwụ ọtọ na-ebuli gia dị n’ime site na mkpanaka na-emegharị ahụ ma debe workpiece na nhazi ọkwa n’okpuru. ihe mmetụta. Enwere mgba ọkụ abụọ nso nso ejiri dị ka ihe ngosi ndokwa raara onwe ya nye. Ọ bụrụ na edobere ọnọdụ na-ezighi ezi, workpiece Ya bụ, laghachi na mkpanaka na-emegharị ihe maka imeju. Ebe a na-ekwesịghị ekwesị bụ, ngwa igwe na-akwụsị ịgba ọsọ, ma n’otu oge ahụ, ihuenyo ngosipụta nchọpụta na-egosi na workpiece adịghị na ọdụ nkwụsị. Ọ bụrụ na edobere gia dị n’ime ya nke ọma wee nabata ya site na ọdụ nghazi workpiece, usoro nyocha ga-eziga ya na ihe mmetụta. Ozugbo ihe mmetụta dị n’ime gia dị n’ime, ọkụ ọkụ etiti etiti na-amalite ikpo ọkụ, ọrụ ahụ na-atụgharị, na usoro nyocha na-ebelata workpiece, nke mere na ihe mmetụta na-enyocha ma na-ekpo ọkụ n’ogologo nke ngwa ahụ. Eserese eserese nke ime gia etiti oge preheating na nchacha oge dị elu ka egosiri na eserese 8-46.

Mgbe emechara preheating nke etiti, onye na-enyocha nyocha na-ebili ma laghachi n’ọnọdụ mbụ, a na-agbanye ọkụ ọkụ na nnukwu ọkụ ọkụ ugboro ugboro, ọrụ ahụ na-atụgharị ala ọzọ, a na-enyocha ngwa ahụ preheated ma menyụọ ya ugboro ugboro. Mgbe emenyụchara n’ime gia rịdata na mkpanaka na-emegharị emegharị, mkpanaka na-emegharị ahụ na-ebugharị workpiece na ọdụ tempering, na akara ngosi ọnọdụ ya bụ otu ihe ahụ dị ka ọdụ ụgbọ mmiri ahụ. Tempering bụ usoro kpo oku otu oge, workpiece na-atụgharị n’oge okpomọkụ, na ike ọkụ dị ntakịrị, a na-eme ya n’oge oge siri ike nke ngwa ngwa.

Mgbe tempering usoro dechara, gia na-agbada na reciprocating mkpara na-akwaga na jụrụ ọdụ, mma site ịgba isi na loading na ebutu okpomọkụ, na mgbe ahụ workpiece na-akwaga na sub-nlele ọdụ (ruru eru ma ọ bụ jụrụ). ). A na-ekpebi ọjụjụ site na ọtụtụ ngwaọrụ nchọpụta. Ọ bụrụ na ekpebie na a ga-ajụ gia dị n’ime ahụ, mkpanaka pneumatic nke arụnyere n’akụkụ ga-agbanye ngwa ahụ n’ahịrị ma banye na igbe nchụpụ ajụ. Ọ bụrụ na ngwa ahụ tozuru oke, pịazie na igbe ntọhapụ.

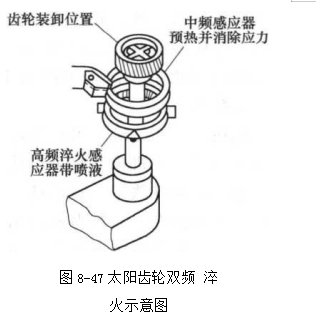

(2) Nkwụsị na iwe ọkụ nke ngwa anyanwụ A na-egosi eserese mbelata ugboro abụọ nke ngwa anyanwụ na foto 8-47.

N’oge etiti ugboro preheating na elu ugboro kpo oku, workpiece na-atụgharị. Mgbe ikpo ọkụ dị elu ugboro ugboro, a na-efesa mmiri na-ekpo ọkụ site na inductor jikọtara. N’ihi njirimara nhazi nke ngwa anyanwụ, a ghaghị iwepụ mmiri mmiri na-ekpo ọkụ tupu ọ abanye n’ọdụ ọkụ. Enwere ebe a na-ama jijiji na-arụ ọrụ nke na-ebuli ngwa anyanwụ ruo 110. N’akuku na ịma jijiji iji wepụ mmiri mmiri na-emenyụ agbakwunyere. Usoro iwe ọkụ na-eji oge etiti, nke na-eme ka ọ bụrụ oge maka ikpo ọkụ dị elu nke ngwa a. N’oge tempering, workpiece na-atụgharịkwa, na ngwa ngwa gia na-abanye n’ọdụ jụụ. Mgbe ịgbara jụrụ oyi, ọ na-ama jijiji ọzọ. Mgbe dewatering gasịrị, ọ na-abanye n’ọdụ nyocha maka ndị ruru eru na ịjụ nhazi.

(3) Nchọpụta ngwá ọrụ na njikwa ya A na-achịkwa ngwa ngwa nyocha, usoro ikpo ọkụ na ikpo ọkụ na-ekpo ọkụ bụ onye mmemme (Modicon 984), yana kaadị ntinye na mmepụta ihe, na onye mmemme (480).

A na-eji Gould), onye na-ahụ maka servo (410 Gould), onye na-ahụ maka moto DC iji chịkwaa ọsọ ntụgharị nke workpiece. A na-eji njikwa servo iji chịkwaa ọsọ nyocha, ihuenyo nchoputa mmejọ na-egosiputa mmejọ ahụ, ihe nleba anya ike na-enye ezigbo ume. Ihe mmetụta na-emenyụ ọkụ na-ekpo ọkụ nwere nchebe n’ala. Ọ bụrụ na workpiece na-adaba na ihe mmetụta ahụ, a ga-egosipụta mmejọ ahụ na ihuenyo na ngwaọrụ igwe ga-akwụsị ịrụ ọrụ.

(4) Usoro nju oyi nke mmiri mejupụtara igwe anaghị agba nchara, igwe na-ekpo ọkụ na-ekpo ọkụ, ihe ngbanwe na-ese n’elu mmiri, ihe nleba anya mmiri mmiri, na valvụ thermostat akpaka.