- 08

- Aug

Ngabe ulayini wokukhiqiza ocisha igiya ophindwe kabili wokucisha umlilo usebenza kanjani?

Igiya le-double-frequency lisebenza kanjani induction Ukushisa isithando somlilo umsebenzi womugqa wokukhiqiza?

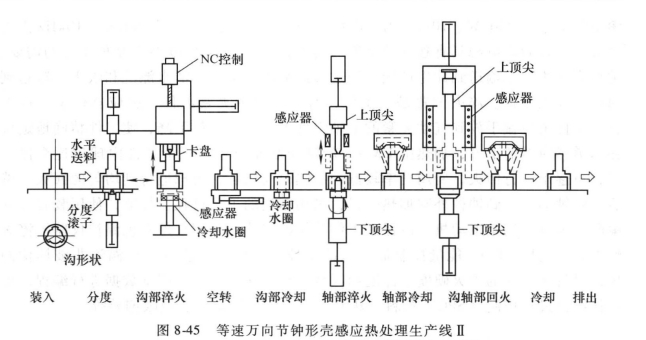

Inkampani yaseMelika i-TOCC0 yake yaklama futhi yakha isithando somlilo esinezikhawu ezimbili zokucisha nokucisha ulayini wokukhiqiza wamagiya angaphakathi namagiya elanga embonini yokudlulisela. Lo mugqa wokukhiqiza uqukethe amandla amabili we-solid-state amabili angu-100kW, 10kHz, eyodwa eyegiya langaphakathi enye eyegiya lelanga; ugesi wemvamisa ephezulu ungu-200kW, 450kHz.

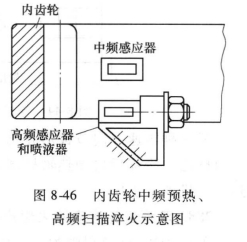

Ukucisha kanye nokushiswa kwamagiya angaphakathi Amagiya angaphakathi alo mzila wokukhiqiza ehliswa ucezu olulodwa ngesikhathi futhi asebenza ngamasilinda amabili aphikiswayo. Uma i-workpiece isendaweni yokulayisha engu-No. 1, i-proximity switch isebenza ukwenza induku ephindaphindayo ye-pneumatic iphushele ucezu lokusebenza esiteshini sokucisha. Lesi siteshi sine-servo enesivinini esiguquguqukayo kanye nobakaki wokuskena ume mpo, igiya lifinyelela esiteshini sokucisha, kanti elinye I-proximity switch iyasebenza, ngakho isithwebuli esiqondile siphakamisa igiya langaphakathi entweni ebuyiselayo bese sibeka ucezu lokusebenza endaweni yokuma ngaphansi kwe-orientation. inzwa. Kunokushintsha okubili kokusondelana okusetshenziswe njengesikhombi sokuma esizinikele. Uma isikhundla esingalungile sisethiwe, i-workpiece Okungukuthi, buyela entongeni yokubuyisela ukuze ugcwalise kabusha. I-Misplacement Ingabe, ithuluzi lomshini liyayeka ukusebenza, futhi ngesikhathi esifanayo, isikrini sokubonisa ukuxilonga sibonisa ukuthi i-workpiece ayikho esiteshini sokucisha. Uma igiya langaphakathi libekwe ngendlela efanele futhi lamukelwa yisiteshi sokuma kwengcezu yokusebenza, indlela yokuskena izoyithumela kunzwa. Uma inzwa isitholakala egiyeni langaphakathi, amandla ogesi aphakathi nendawo aqala ukushisa, ucezu lokusebenza luyazungeza, futhi indlela yokuskena yehlisa ucezu lokusebenza, ukuze inzwa iskena futhi ishise ubude obugcwele begiya langaphakathi. Umdwebo wohlelo lwegiya langaphakathi lokushisisa kwamafrikhwensi aphakathi nendawo kanye nokucishwa kwefrikhwensi ephezulu kubonisiwe kuMfanekiso 8-46.

Ngemva kokuphothulwa kokushisisa kwefrikhwensi ephakathi nendawo, i-positioner yokuskena iyakhuphuka futhi ibuyele endaweni yokuqala, inkinobho yamandla ishintshelwa kugesi wefrikhwensi ephezulu, i-workpiece izungeza phansi futhi, futhi igiya elishisiwe liyaskenwa futhi licinywe ngefrikhwensi ephezulu. Ngemva kokuba igiya langaphakathi elicishiwe lehlela endukwini ebuyiselayo, induku ebuyiselayo iphusha ucezu lokusebenza esiteshini sokufudumeza, futhi isenzo sayo sesignali sokuma siyefana nesesiteshi sokucisha. I-Tempering iyindlela yokushisa yesikhathi esisodwa, i-workpiece iyajikeleza ngesikhathi sokushisa, futhi amandla okushisa mancane, futhi yenziwa ngesikhathi sokuqina kwe-high-frequency yegiya.

Ngemuva kokuthi inqubo yokushisa isiqediwe, igiya lehliselwa entongeni ephindaphindayo bese liphushwa esiteshini sokupholisa, lipholiswe ikhanda lesifutho liye endaweni yokushisa yokulayisha nokuthulula, bese i-workpiece iphushwa esiteshini sokuhlola esincane (esifanelekayo noma senqatshiwe. ). Ukwenqatshwa kunqunywa imishini eminingi yokuthola. Uma igiya langaphakathi kunqunywa ukuthi linqatshiwe, induku yokukhipha umoya efakwe eceleni izophusha igiya iye ngokuvundlile bese ishelela ebhokisini lokukhipha lokwenqaba. Uma igiya lifanelekile, phushela ebhokisini lokukhipha.

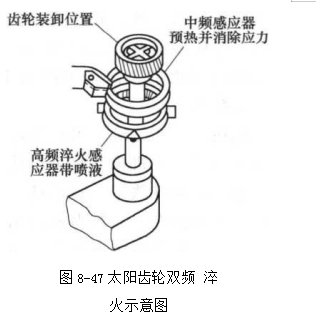

(2) Ukucisha kanye nokufudumeza kwegiya lelanga Umdwebo wokucisha ophindwe kabili wegiya lelanga ukhonjiswe kuMfanekiso 8-47.

Ngesikhathi sokushisisa kwefrikhwensi ephakathi nendawo kanye nokushisa kwefrikhwensi ephezulu, i-workpiece iyajikeleza. Ngemuva kokushisa kwemvamisa ephezulu, uketshezi lokucisha lufafazwa ku-inductor ehlanganisiwe. Ngenxa yezici zesakhiwo segiya lelanga, uketshezi olucishayo kufanele lususwe ngaphambi kokuthi lungene esiteshini sokufudumeza. Kukhona isiteshi sokukhanya sokunyakazisa ukukhanya esiphakamisa igiya lelanga liye ku-110. I-engeli bese unyakazisa ukuze ususe uketshezi lokucisha olunamathiselwe. Inqubo yokuthambisa isebenzisa imvamisa emaphakathi, okwenzeka isikhathi sokushisisa imvamisa ephezulu yaleli giya. Ngesikhathi sokushisa, i-workpiece nayo iyajikeleza, futhi igiya elithambile lingena esiteshini sokupholisa. Ngemva kokupholisa isifutho, siyazamazama futhi. Ngemuva kokususwa kwamanzi, ingena esiteshini sokuhlola ukuze ihlungwe futhi yenqabe.

(3) Ithuluzi lokuhlonza nokulawula kwalo Isivinini sokuskena, umjikelezo wokushisisa nokupholisa kokucisha kulawulwa umdidiyeli (i-Modicon 984), kanye namakhadi okokufaka nawokukhiphayo, kanye nomdidiyeli (480)

Gould), isilawuli se-servo (410 Gould), isilawuli semoto ye-DC sisetshenziselwa ukulawula isivinini sokuzungezisa isiqeshana sokusebenza. Isilawuli se-servo sisetshenziselwa ukulawula isivinini sokuskena, isikrini sokuxilongwa kwephutha sibonisa iphutha, futhi isiqaphamandla samandla sinikeza amandla wangempela. Izinzwa zokucisha kanye nezipholile zinokuvikeleka okuphansi. Uma i-workpiece ishayisana nenzwa, iphutha lizoboniswa esikrinini futhi ithuluzi lomshini lizoyeka ukusebenza.

(4) Isistimu yokupholisa amanzi yenziwe ngephampu yamanzi yensimbi engagqwali, isishintshi sokushisa samapuleti, isishintshi se-float, isiqapha lokushisa samanzi, kanye ne-automatic thermostat valve.