- 28

- Nov

Dab tsi yog cov refractory cib feem ntau siv hauv ferroalloy hluav taws xob rauv taws

Dab tsi yog cov refractory cib feem ntau siv hauv ferroalloy hluav taws xob rauv taws

Ferroalloy electric furnace refractories muaj xws li peb qhov chaw: lub qhov cub ru tsev refractories, rauv phab ntsa refractories thiab molten pas dej ua ke refractories (kub qhov nqes hav thiab cub hauv qab). Nyob rau hauv tus txheej txheem ntawm ferroalloy smelting, qhov sib txawv ntawm refractories nyob rau hauv txawv kev ua hauj lwm.

Cov khoom siv hluav taws xob sab saum toj kawg nkaus yog cuam tshuam los ntawm kev yaig thiab cuam tshuam ntawm cov cua kub kub thiab cov tshuaj tsuag slag, qhov kub thiab txias hloov ntawm lub sijhawm pub mis thiab radiant tshav kub ntawm high-temperature arc, qhov cuam tshuam ntawm airflow thiab siab hloov thaum lub sij hawm cov khoom tawg.

Rauv phab ntsa refractories mas dais lub high-kub hluav taws xob nyhuv ntawm lub arc thiab kub hloov thaum lub sij hawm them nyiaj lub sij hawm; erosion thiab cuam tshuam ntawm high-temperature furnace gas thiab sprayed slag; cuam tshuam thiab abrasion ntawm cov khoom siv thiab cov khoom semi-molten; hnyav slag corrosion thiab corrosion nyob ze ntawm slag kab Kev cuam tshuam ntawm slag. Tsis tas li ntawd, thaum lub cub tawg lub cev qaij, nws kuj dais siab ntxiv.

Lub cub hluav taws xob nqes hav thiab hauv qab refractories mas dais lub siab ntawm lub sab sauv txheej los yog molten hlau; qhov cuam tshuam ntawm qhov kub thiab txias hloov, cuam tshuam thiab arc melting poob thaum lub sijhawm them nyiaj; qhov yaig thiab cuam tshuam ntawm kub kub molten hlau thiab molten slag.

Txhawm rau kom ntseeg tau tias lub qhov cub hluav taws xob tuaj yeem ua haujlwm ib txwm, nws yog ib qho tsim nyog yuav tsum xaiv cov khoom siv refractory nrog siab refractoriness thiab load softening kub, zoo tiv thaiv kom ceev txias thiab kub thiab slag tsis kam, loj kub muaj peev xwm thiab tej yam thermal conductivity los tsim lub cub hluav taws xob. hauv ob sab phlu.

Kev ua tau zoo thiab siv cov yam ntxwv ntawm lub tshuab hluav taws xob hauv ob sab phlu refractories feem ntau siv hauv kev tsim cov ferroalloys yog raws li hauv qab no.

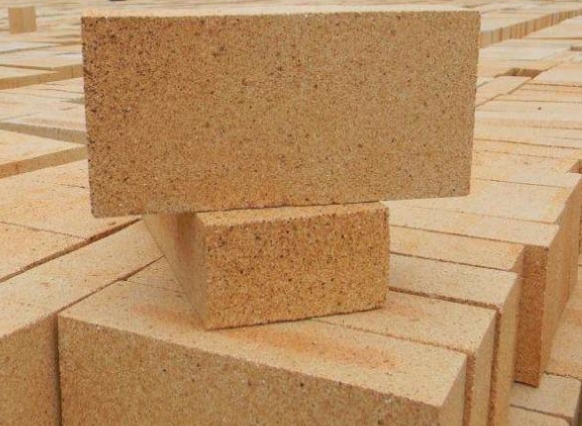

1. av nplaum cib

Lub ntsiab raw khoom rau ua av nplaum cib yog refractory av nplaum nrog zoo plasticity thiab adhesion.

Cov yam ntxwv tseem ceeb ntawm cov av nplaum cib yog: muaj zog tiv taus cov kua qaub slag, zoo tiv thaiv kom txias thiab kub ceev, zoo thaum tshav kub kub preservation thiab tej yam rwb thaiv tsev zog; low refractoriness thiab load softening kub. Cov av nplaum yuav tsum tsis txhob siv ncaj qha rau hauv qhov kub thiab txias thiab cov kev cai tshwj xeeb.

Hauv kev tsim cov ferroalloys, av nplaum cib feem ntau yog siv rau kev tso cua sov phab ntsa thiab hauv ob sab phlu ntawm qhov chaw ntawm submerged arc furnaces, rauv phab ntsa thiab lub cub tawg hauv qab txheej txheej rau kev txuag hluav taws xob thiab rwb thaiv tsev, lossis rau kev tso cov ladle linings.

2. High alumina cib

Lub ntsiab raw khoom rau kev ua siab alumina cib yog siab alumina bauxite, thiab cov binder yog refractory av nplaum.

Piv nrog cov av nplaum cib, qhov zoo tshaj plaws ntawm cov alumina cib yog siab refractoriness, siab load softening degree, zoo slag kuj thiab siab mechanical zog. Qhov tsis zoo yog tias cov high-alumina cib muaj qhov tsis zoo rau kev ua kom txias thiab cua sov sai.

Nyob rau hauv kev tsim cov ferroalloys, high-alumina cib tuaj yeem siv los tsim submerged arc rauv taphole hauv ob sab phlu, refining sab saum toj ntawm hluav taws xob rauv, thiab tseem tuaj yeem siv los tsim cov hlau nplaum hauv ob sab phlu.

3. Magnesia cib thiab magnesia

Cov khoom siv tseem ceeb rau kev ua cov pob zeb magnesia yog magnesite, thiab cov binder yog dej thiab brine lossis sulfite pulp pov tseg kua.

Cov yam ntxwv tseem ceeb ntawm magnesia bricks yog: siab refractoriness thiab zoo heev tiv thaiv alkaline slag; tab sis cov thermal conductivity thiab hluav taws xob conductivity ntawm qhov kub thiab txias yog qhov loj, thiab cov load softening kub yog tsawg, thiab ceev ceev cua txias thiab cua sov kuj tsis zoo. Pulverization tshwm sim thaum raug dej los yog chav ntawm qhov kub thiab txias.

Hauv kev tsim cov ferroalloys, magnesia bricks yog siv los tsim high-carbon ferrochrome txo hluav taws xob rauv, nruab nrab thiab qis-carbon ferrochrome converters, shakers thiab refining hluav taws xob rauv phab ntsa, rauv hauv qab, thiab kub hlau ladle uas muaj ferrochrome thiab nruab nrab-tsawg carbon ferromanganese. Hauv ob sab phlu thiab lwm yam. Siv magnesia alumina bricks es tsis txhob magnesia cib los tsim lub ru tsev rauv taws. Magnesia muaj siab refractoriness. Hauv kev tsim cov ferroalloys, magnesia feem ntau yog siv rau knotting furnace bottoms, ua thiab kho cov phab ntsa rauv thiab lub cub tawg hauv qab, thiab ua cov khoom siv rau ntsaws qhov los yog ua cov pwm ingoted.

4. Cov cib cib

Cov ntaub ntawv tseem ceeb rau kev ua cov pa roj carbon cib yog crushed coke thiab anthracite, thiab cov binder yog thee tar los yog suab.

Piv nrog rau lwm cov khoom siv refractory, carbon bricks tsis tsuas yog muaj zog compressive, tsis tshua muaj thermal expansion coefficient, zoo hnav tsis kam, siab refractoriness thiab load softening kub, zoo tiv thaiv kom ceev txias thiab kub, thiab tshwj xeeb tshaj yog zoo slag kuj. Yog li ntawd, cov pa roj carbon cib tuaj yeem siv los ua cov ntaub ntawv hauv ob sab phlu rau submerged arc furnaces rau txhua hom ferroalloys uas tsis ntshai carburization.

Txawm li cas los xij, carbon bricks yooj yim heev rau oxidize nyob rau hauv qhov kub thiab txias, thiab lawv cov thermal conductivity thiab hluav taws xob conductivity kuj loj. Hauv kev tsim cov ferroalloys, carbon cib feem ntau yog siv los tsim cov phab ntsa thiab hauv qab ntawm submerged arc furnaces uas tsis raug huab cua.