- 28

- Nov

Yiziphi izitini eziphikisayo ezivame ukusetshenziswa ezithandweni zikagesi ze-ferroalloy

Yiziphi izitini eziphikisayo ezivame ukusetshenziswa ezithandweni zikagesi ze-ferroalloy

I-Ferroalloy electric refractories yesithando somlilo ihlanganisa izingxenye ezintathu: izinqamuleli zophahla lwesithando somlilo, izinsimbi zodonga lwesithando somlilo kanye nezinsimbi ezincibilikisiwe zamachibi (i-slope yesithando somlilo kanye ngezansi kwesithando somlilo). Enqubweni yokuncibilikiswa kwe-ferroalloy, izingxenye ezihlukene ze-refractories zisesimweni esihlukile sokusebenza.

Izinto eziphikisayo eziphezulu zesithando somlilo zithinteka kakhulu ngokuguguleka kanye nomthelela wegesi yokushisa yokushisa ephezulu kanye ne-slag efuthwe, izinga lokushisa liyashintsha phakathi kwezikhathi zokudla kanye nokushisa okukhazimulayo kwe-arc yokushisa okuphezulu, umthelela wokugeleza komoya kanye noshintsho lwengcindezi ngesikhathi sokuwa kwezinto ezibonakalayo.

Ama-refractories odongeni lwesithando somlilo ikakhulukazi aphethe umphumela wokushisa ophezulu we-arc kanye nezinga lokushisa eliguqukayo ngesikhathi sokushaja; ukuguguleka nomthelela wegesi yesithando sokushisa ephezulu kanye ne-slag efuthwe; umthelela kanye nokuhuzuka kwezinto eziqinile kanye nezinto ezincibilikisiwe kancane; ukugqwala okukhulu kwe-slag kanye nokugqwala eduze komugqa we-slag Umthelela we-slag. Ngaphezu kwalokho, lapho umzimba wesithando somlilo utsheka, nawo uthwala ingcindezi eyengeziwe.

Umthambeka wesithando somlilo kanye nezindawo eziphikisayo ezingezansi ikakhulukazi zithwala ukucindezela kongqimba olungaphezulu lweshaja noma insimbi encibilikisiwe; umthelela wokushintsha kwezinga lokushisa, umthelela wokushaja kanye nokulahlekelwa kokuncibilika kwe-arc ngesikhathi sokushaja; ukuguguleka nomthelela wokushisa okuphezulu kwensimbi encibilikisiwe kanye ne-slag encibilikisiwe.

Ukuze kuqinisekiswe ukuthi isithando somlilo sikagesi singasebenza ngokujwayelekile, kuyadingeka ukukhetha izinto eziphikisayo ezine-refractoriness ephezulu kanye nezinga lokushisa lokunciphisa umthwalo, ukumelana kahle nokubandayo okusheshayo nokushisa nokumelana ne-slag, umthamo omkhulu wokushisa kanye ne-conductivity ethile yokushisa ukuze kwakhiwe isithando somlilo kagesi. ulwelwesi.

Izici zokusebenza nokusetshenziswa kwezinqamuleli zokufakwa kwesithando somlilo ezivame ukusetshenziswa ekukhiqizeni ama-ferroalloys zimi kanje.

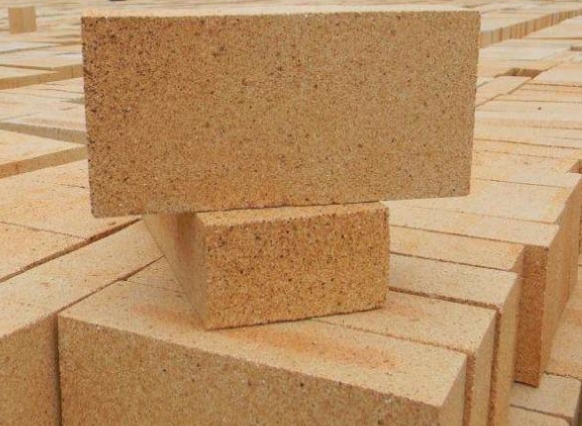

1. Izitini zobumba

Impahla eluhlaza eyinhloko yokwenza izitini zobumba ubumba oluphikisayo olunopulasitiki omuhle nokunamathela.

Izici eziyinhloko zokusebenza kwezitini zobumba yilezi: ukumelana okuqinile ne-asidi slag, ukumelana okuhle emakhazeni asheshayo nokushisa, ukugcinwa okuhle kokushisa kanye nezakhiwo ezithile zokufakelwa; i-refractoriness ephansi kanye nokushisa okuthambisa umthwalo. Izitini zobumba akufanele zisetshenziswe ngokuqondile ngaphansi kwezimo zokushisa eziphakeme kanye nezidingo ezikhethekile.

Ekukhiqizeni ama-ferroalloys, izitini zobumba zisetshenziselwa ngokuyinhloko ukubeka izindonga zesithando somlilo kanye nemigqa yezingxenye eziveziwe zezithando ze-arc ezingaphansi kwamanzi, izindonga zesithando somlilo kanye nezindwangu zangaphandle ezingaphansi kwesithando somlilo ukuze kugcinwe ukushisa nokushisa, noma ukubeka i-ladle linings.

2. Isitini esiphezulu se-alumina

Impahla eluhlaza eyinhloko yokwenza izitini eziphakeme ze-alumina yi-alumina ephezulu ye-alumina, futhi isibopho siwubumba oluphikisayo.

Uma kuqhathaniswa nezitini zobumba, izinzuzo ezinkulu zezitini eziphakeme ze-alumina ziwukuphikisa okuphezulu, izinga eliphezulu lokuthambisa umthwalo, ukumelana okuhle kwe-slag namandla aphezulu emishini. Okubi ukuthi izitini eziphezulu ze-alumina zikwazi ukumelana nokupholisa ngokushesha nokushisa.

Ekukhiqizeni ama-ferroalloys, izitini eziphezulu ze-alumina zingasetshenziswa ukwakha izitini ze-taphole ze-arc esithandweni somlilo, ukucwenga phezulu kwezithando zikagesi, futhi zingasetshenziswa ukwakha imigqa yensimbi encibilikisiwe.

3. Magnesia isitini kanye magnesia

Impahla eluhlaza eyinhloko yokwenza izitini ze-magnesia yi-magnesite, futhi i-binder amanzi ne-brine noma i-sulfite pulp waste liquid.

Izici eziyinhloko zokusebenza kwezitini ze-magnesia yilezi: ukuqina okuphezulu nokumelana okuhle kakhulu ne-alkaline slag; kodwa i-thermal conductivity kanye ne-conductivity kagesi emazingeni okushisa aphezulu kukhulu, futhi izinga lokushisa lokunciphisa umthwalo liphansi, futhi ukupholisa okusheshayo nokushisa ukumelana kumpofu. I-Pulverization kwenzeka lapho kuvezwa amanzi noma isitimu emazingeni okushisa aphezulu.

Ekukhiqizeni ama-ferroalloys, izitini ze-magnesia zisetshenziselwa ukwakha izithando zikagesi zokunciphisa i-ferrochrome enekhabhoni ephezulu, iziguquli ze-ferrochrome ezinekhabhoni emaphakathi nephansi, ama-shaker kanye nokucwengisiswa kwezindonga zesithando somlilo sikagesi, okungaphansi kwesithando somlilo, neladi yensimbi eshisayo equkethe i-ferrochrome ne-carbon ferromanganese ephansi. Ulayini njll. Sebenzisa izitini ze-magnesia alumina esikhundleni sezitini ze-magnesia ukuze wakhe uphahla lwesithando somlilo. I-Magnesia ine-refractoriness ephezulu. Ekukhiqizeni ama-ferroalloys, i-magnesia ivamise ukusetshenziselwa ukuhlanganisa izingezansi zesithando somlilo, ukwenza kanye nokulungisa izindonga zesithando somlilo kanye nezansi zesithando somlilo, futhi njengento yokuxhuma izimbobo noma ukwenza isikhunta se-ingot esinamafindo.

4. Izitini zamalahle

Izinto zokusetshenziswa eziyinhloko zokwenza izitini ze-carbon yi-coke echotshoziwe ne-anthracite, kanti i-binder iyitiyela yamalahle noma i-pitch.

Uma kuqhathaniswa nezinye izinto ezivamile zokuphikisa, izitini ze-carbon azinawo amandla aphezulu okucindezela, i-coefficient ephansi yokwandisa okushisayo, ukumelana nokugqokwa okuhle, ukuphikiswa okuphezulu kanye nezinga lokushisa lokuthambisa umthwalo, ukumelana okuhle emakhazeni asheshayo nokushisa, futhi ikakhulukazi ukumelana ne-slag enhle. Ngakho-ke, izitini zekhabhoni zingasetshenziswa njengezinto zokwenziwa kwezindwangu zama-arc angaphansi kwamanzi azo zonke izinhlobo ze-ferroalloys ezingesabi i-carburization.

Kodwa-ke, izitini ze-carbon zilula kakhulu ukufaka i-oxidize ngaphansi kwezimo zokushisa eziphakeme, futhi ukuqhutshwa kwe-thermal conductivity kanye ne-conductivity kagesi kukhulu kakhulu. Ekukhiqizeni ama-ferroalloys, izitini zekhabhoni zisetshenziselwa ikakhulukazi ukwakha izindonga nezansi zezithando ze-arc ezingaphansi kwamanzi ezingavezwanga emoyeni.