- 28

- Nov

Waa maxay lebenka refractory ee caadi ahaan loo isticmaalo foornooyinka korontada ee ferroalloy

Waa maxay lebenka refractory ee caadi ahaan loo isticmaalo foornooyinka korontada ee ferroalloy

Foornooyinka foornada korontada ee Ferroalloy waxay ka kooban tahay saddex qaybood: refractories saqafka foornada, foornooyinka derbiga foornada iyo barkada dhalaalaysa (jiirada foornada iyo foornada hoose). Habka dhalada ferroalloy, qaybaha kala duwan ee refractories waxay ku jiraan xaalado shaqo oo kala duwan.

Qalabka foornada ee ugu sarreeya waxaa inta badan saameeya nabaad-guurka iyo saameynta gaaska foornada heerkulka sare leh iyo dhirbaaxada la buufiyo, heerkulka isbeddelka ee u dhexeeya waqtiyada quudinta iyo kulaylka iftiinka ee heerkulka sare ee arc, saameynta socodka hawada iyo cadaadiska isbeddelka inta lagu jiro burburka alaabta.

Dib-u-celinta gidaarada foornada waxay inta badan sidataa saameynta shucaaca heerkulka sare ee arc iyo heerkulka isbeddelka inta lagu jiro muddada dallacaadda; nabaad guurka iyo saamaynta gaasta foornada kuleylkeedu sarreeyo iyo dharbaaxo la buufiyay; Saamaynta iyo xoqidda maaddooyinka adag iyo walxaha dhalaalka ah; Daxalka iyo daxalka u dhow khadka slag Saamaynta slag. Intaa waxaa dheer, marka jirku foornada uu foorarsado, waxay sidoo kale leedahay cadaadis dheeraad ah.

Jiirada foornada iyo refractors hoose waxay inta badan qaadaan cadaadiska lakabka sare ee kharashka ama birta dhalaalaysa; Saamaynta isbeddelka heerkulka, saamaynta kharashka iyo luminta dhalaalka arc inta lagu jiro muddada dallacaadda; Nabaadguurka iyo saamaynta heerkulka sare ee birta dhalaalaysa iyo dhalaalka.

Si loo hubiyo in foornada korantada ay si caadi ah u shaqeyn karto, waxaa lagama maarmaan ah in la doorto qalabka dib-u-soo-celinta leh heerkulka sare ee jilicsanaanta iyo culeyska culeyska, caabbinta wanaagsan ee qabow degdeg ah iyo kulaylka iyo caabbinta slag, awoodda kulaylka weyn iyo heerkulka kuleylka qaarkood si loo dhiso foornada korontada dahaarka.

Waxqabadka iyo sifooyinka isticmaalka foornooyinka foornada foornada ee inta badan loo isticmaalo soo saarista ferroalloys waa sida soo socota.

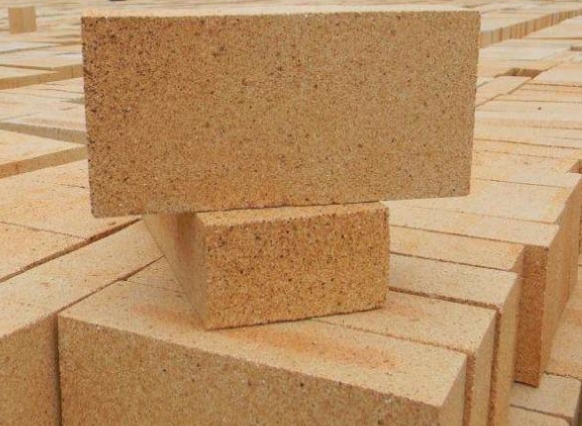

1. Leben dhoobo ah

Waxyaabaha ugu muhiimsan ee alaabta ceeriin ee samaynta leben dhoobada ah waa dhoobo celin leh oo leh caag wanaagsan iyo dhejis.

Astaamaha waxqabadka ugu weyn ee leben dhoobada ah waa: iska caabin adag oo u adkaysta slag acid, caabbinta wanaagsan ee qabow iyo kulaylka degdega ah, ilaalinta kulaylka wanaagsan iyo sifooyinka ilaalinta qaarkood; refractorness hoose iyo heerkulka jilcisa. Leben dhoobo ah waa inaan si toos ah loogu isticmaalin xaaladaha heerkulka sare iyo shuruudaha gaarka ah.

Soo saarista ferroalloys-ka, lebenka dhoobada ah ayaa inta badan loo adeegsadaa jeexista darbiyada foornada iyo dahaarka qaybaha foornooyinka foornooyinka hoostooda, darbiyada foornada iyo foornada dahaarka hoose ee foornada ee ilaalinta kulaylka iyo dahaarka, ama jeexista dahaarka saqafka.

2. Leben sare oo aluminium ah

Qalabka ugu muhiimsan ee samaynta lebenka aluminiumka sare waa alumina bauxite sare, iyo xidhehu waa dhoobo refractory.

Marka la barbardhigo lebenka dhoobada ah, faa’iidooyinka ugu weyn ee lebenka aluminiumka sare waa refractorness sare, heerka jilicsanaanta culeyska sare, caabbinta caabbinta wanaagsan iyo xoogga farsamada sare. Khasaaraha ayaa ah in lebennada aluminiumka ah ay leeyihiin iska caabin liidata ee qaboojinta degdega ah iyo kuleylka.

Soo saarista ferroalloys-ka, leben-alumina-ga sare leh ayaa loo isticmaali karaa in lagu dhiso lebennada dahaarka ah ee foornada hoose ee foornada, sifaynta dusha sare ee foornooyinka korontada, iyo sidoo kale waxaa loo isticmaali karaa in lagu dhiso dahaarka dhalaalka ah ee birta ah.

3. Magnesia leben iyo magnesia

Waxyaabaha ugu muhiimsan ee ceeriin ee samaynta lebenka magnesia waa magnesite, iyo xiraha waa biyo iyo brine ama dareeraha qashinka saxarka sulfite.

Tilmaamaha waxqabadka ugu muhiimsan ee lebenka magnesia waa: dib-u-celinta sare iyo iska caabbinta aadka u fiican ee caleenta alkaline; laakiin heerkulka kulaylka iyo korantada heerkulka sare waa weyn yahay, heerkulka jilcintuna waa yar yahay, qaboojinta degdega ah iyo kuleylka kuleylka ayaa liita. Burburinta waxay dhacdaa marka ay la kulmaan biyaha ama uumiga heerkulka sare.

Soo saarista ferroalloys, lebenka magnesia waxaa loo isticmaalaa in lagu dhiso foornooyinka koronto-yar ee kaarboon-kaarboon-sare, beddelayaasha ferrochrome dhexdhexaad ah iyo kaarboon-yar, ruxruxo iyo nadiifinta darbiyada foornada korantada, gunta foornada, iyo birta kulul ee ka kooban ferrochrome iyo ferromanganese kaarboon dhexdhexaad ah Dahaarka iwm. Isticmaal lebenka magnesia alumina halkii aad ka isticmaali lahayd lebenka magnesia si aad u dhisto saqafka foornada. Magnesia waxay leedahay refractoriness sare. Soo saarista ferroalloys, magnesia ayaa inta badan loo isticmaalaa in lagu xidho gunta foornada, samaynta iyo hagaajinta darbiyada foornada iyo foornada guntooda, iyo sida wax lagu xidho godadka ama samaynta caaryada guntimaha ah.

4. Leben dhuxusha

Qalabka ugu muhiimsan ee laga sameeyo leben kaarboon waa kookaha iyo anthracite oo la shiiday, xiruhuna waa daamur dhuxul ah ama daamur.

Marka la barbardhigo walxaha kale ee dib-u-celinta caadiga ah, lebenka kaarboonka kaliya maaha inay leeyihiin xoog cadaadis sare leh, iskudhafka ballaarinta kulaylka hooseeya, caabbinta xirashada wanaagsan, qaboojinta sare iyo heerkulka jilciya, iska caabin wanaagsan oo qabow iyo kulayl degdeg ah, iyo gaar ahaan iska caabin wanaagsan. Sidaa darteed, leben kaarboonka waxaa loo isticmaali karaa sida alaabta dahaarka ee foornooyinka arc hoostooda ee dhammaan noocyada ferroalloys ee aan ka cabsanayn carburization.

Si kastaba ha ahaatee, lebenka kaarboonku aad bay ugu fududahay in ay oksaydheeyaan xaaladaha heerkulka sare, iyo kuleylkooda iyo korantada korantada ayaa aad u weyn. Soo saarista ferroalloys-ka, leben kaarboon ayaa inta badan loo isticmaalaa in lagu dhiso gidaarada iyo guntooda foornooyinka dhulka hoostiisa mara ee aan hawada soo galin.