- 28

- Nov

Ke litene tsa refractory tse atisang ho sebelisoa liboping tsa motlakase tsa ferroalloy

Ke litene tsa refractory tse atisang ho sebelisoa liboping tsa motlakase tsa ferroalloy

Li-refractories tsa sebōpi sa Ferroalloy li kenyelletsa likarolo tse tharo: li-refractories tsa marulelo a sebōpi, li-refractories tsa lebota la sebōpi le li-refractories tse qhibilihantsoeng tsa letamo (moepa oa sebōpi le tlaase ea sebōpi). Ts’ebetsong ea ho qhibiliha ha ferroalloy, likarolo tse fapaneng tsa li-refractories li maemong a fapaneng a ts’ebetso.

Lisebelisoa tsa top refractory tsa sebōpi li angoa haholo ke khoholeho ea mobu le tšusumetso ea khase ea mocheso oa mocheso o phahameng oa mocheso le slag e fafalitsoeng, mocheso o fetoha pakeng tsa nako ea ho fepa le mocheso o khanyang oa mocheso o phahameng oa arc, phello ea ho phalla ha moea le khatello ea khatello nakong ea ho oa ha thepa.

Li-refractories tsa lerako la sebōpi haholo-holo li na le phello e phahameng ea mocheso oa mahlaseli a arc le liphetoho tsa mocheso nakong ea nako ea ho tjhaja; khoholeho le phello ea khase ea sebōpi se nang le mocheso o phahameng le slag e fafalitsoeng; tšusumetso le ho senyeha ha thepa e tiileng le thepa e entsoeng ka halofo e qhibilihisitsoeng; ho bola ho matla le ho bola haufi le mola oa slag Impact of slag. Ho phaella moo, ha ‘mele oa sebōpi o sekama, o boetse o jara khatello e eketsehileng.

Moepa oa sebōpi le li-refractories tse tlase haholo-holo li na le khatello ea lera le ka holimo la tefiso kapa tšepe e qhibilihisitsoeng; phello ea liphetoho tsa mocheso, tšusumetso ea tefiso le tahlehelo ea ho qhibiliha ha arc nakong ea nako ea ho tjhaja; khoholeho le phello ea mocheso o phahameng oa tšepe e qhibilihisitsoeng le slag e qhibilihisitsoeng.

E le ho etsa bonnete ba hore sebōpi sa motlakase se ka sebetsa ka mokhoa o tloaelehileng, hoa hlokahala ho khetha thepa ea refractoriness e nang le refractoriness e phahameng le mocheso o nolofatsang mojaro, ho hanyetsa hantle ho batang ka potlako le mocheso le ho hanyetsa ha slag, matla a maholo a mocheso le conductivity e itseng ea mocheso ho haha sebōpi sa motlakase. lesela.

Litšobotsi tsa ts’ebetso le ts’ebeliso ea li-refractories tsa lesela la sebōpi tse atisang ho sebelisoa ha ho etsoa li-ferroalloys ke tse latelang.

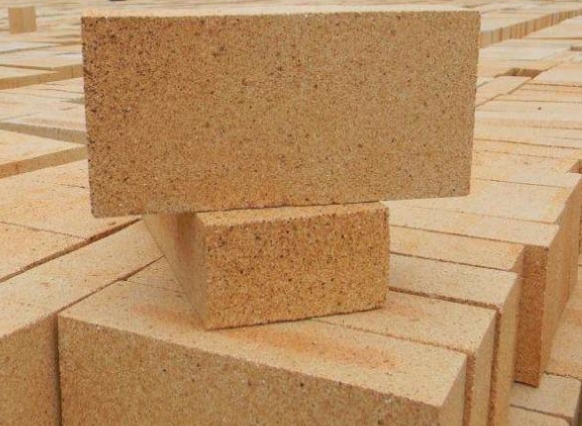

1. Litene tsa letsopa

Lintho tse ka sehloohong tse tala bakeng sa ho etsa litene tsa letsopa ke letsopa le refractory le polasetiki e ntle le ho khomarela.

Litšobotsi tse ka sehloohong tsa ts’ebetso ea litene tsa letsopa ke: ho hanyetsa ka matla ho slag ea acid, ho hanyetsa hantle serame se potlakileng le mocheso, ho boloka mocheso o motle le thepa e itseng ea ho pata; tlaase refractoriness le mojaro softening mocheso. Litene tsa letsopa ha lia lokela ho sebelisoa ka ho toba tlas’a maemo a phahameng a mocheso le litlhoko tse khethehileng.

Ha ho etsoa li-ferroalloys, litene tsa letsopa li sebelisoa haholo-holo bakeng sa ho rala mabota a sebōpi le masela a likarolo tse pepeneneng tsa libono tse kentsoeng ka tlas’a metsi, mabota a sebōpi le masela a ka ntle a sebōpi bakeng sa ho boloka mocheso le ho kenya letsoho, kapa ho beha lilakane tsa ladle.

2. Setene se phahameng sa alumina

Lintho tse ka sehloohong tse tala bakeng sa ho etsa litene tse phahameng tsa alumina ke alumina bauxite e phahameng, ‘me se tlamang ke letsopa le refractory.

Ha ho bapisoa le litene tsa letsopa, melemo e meholo ka ho fetisisa ea litene tse phahameng tsa alumina ke ho refractoriness e phahameng, tekanyo e phahameng ea ho nolofatsa mojaro, khanyetso e ntle ea slag le matla a phahameng a mochini. Bothata ke hore litene tse phahameng tsa alumina li na le khanyetso e fokolang ea ho pholile ka potlako le ho futhumatsa.

Ha ho etsoa li-ferroalloys, litene tsa aluminium tse phahameng li ka sebelisoa ho haha litene tse koahetsoeng ka tlas’a metsi arc taphole, ho hloekisa holim’a libōpi tsa motlakase, hape li ka sebelisoa ho haha lisela tse entsoeng ka tšepe e qhibilihisitsoeng.

3. Setene sa Magnesia le magnesia

Lintho tse ka sehloohong tse tala bakeng sa ho etsa litene tsa magnesia ke magnesite, ‘me se tlamang ke metsi le brine kapa sulfite pulp litšila tsa metsi.

Litšobotsi tse ka sehloohong tsa ts’ebetso ea litene tsa magnesia ke: refractoriness e phahameng le khanyetso e babatsehang ea slag ea alkaline; empa conductivity ea mocheso le motlakase oa motlakase ka mocheso o phahameng o moholo, ‘me mocheso o nolofatsang mojaro o tlaase,’ me ho hanyetsa ho pholile ka potlako le ho futhumatsa ho futsanehile. Pulverization e etsahala ha e pepeselitsoe metsing kapa mouoane ka mocheso o phahameng.

Ha ho etsoa li-ferroalloys, litene tsa magnesia li sebelisetsoa ho haha libono tsa motlakase tse fokotsang carbon ferrochrome, li-converter tsa ferrochrome tse mahareng le tse tlaase, li-shaker le ho hloekisa marako a sebōpi sa motlakase, libotlolo tsa sebōpi le ladle ea tšepe e chesang e nang le ferrochrome le carbon ferromanganese e tlaase. Lining joalo-joalo Sebelisa litene tsa magnesia alumina ho e-na le litene tsa magnesia ho haha marulelo a sebōpi. Magnesia e na le khatello e phahameng ea mali. Ha ho etsoa li-ferroalloys, magnesia e atisa ho sebelisoa bakeng sa ho koala likoti tsa sebōpi, ho etsa le ho lokisa mabota a sebōpi le libotlolo tsa sebōpi, hape e le thepa ea ho koala likoti kapa ho etsa liforomo tsa knotted.

4. Litene tsa mashala

Lisebelisoa tse ka sehloohong tsa ho etsa litene tsa carbon ke coke le anthracite e pshatlehileng, ‘me se tlamang ke sekontiri sa mashala kapa sekontiri.

Ha ho bapisoa le lisebelisoa tse ling tse tloaelehileng tsa refractory, litene tsa k’habone ha li na matla a matla a ho hatella feela, coefficient e tlase ea ho atolosoa ha mocheso, khanyetso e ntle ea ho apara, ho hanyetsa ho hoholo le mocheso o bonolo oa mojaro, ho hanyetsa serame se potlakileng le mocheso, haholo-holo ho hanyetsa slag. Ka hona, litene tsa khabone li ka sebelisoa e le lisebelisoa tsa lesela bakeng sa libono tsa arc tse ka tlas’a metsi bakeng sa mefuta eohle ea li-ferroalloys tse sa tšabe carburization.

Leha ho le joalo, litene tsa carbon li bonolo haholo ho oxidize tlas’a maemo a phahameng a mocheso, ‘me conductivity ea bona ea mocheso le motlakase oa motlakase li batla li le khōlō. Ha ho etsoa li-ferroalloys, litene tsa carbon li sebelisoa haholo-holo ho haha marako le botlaaseng ba libono tse kentsoeng ka tlas’a metsi tse se nang moea.