- 28

- Nov

Kedu ihe bụ brik na-emegharị emegharị nke a na-ejikarị na ọkụ eletrik ferroalloy

Kedu ihe bụ brik na-emegharị emegharị nke a na-ejikarị na ọkụ eletrik ferroalloy

Igwe ọkụ ọkụ Ferroalloy eletrik gụnyere akụkụ atọ: ihe nrụpụta ụlọ ọkụ, ihe nrụnye mgbidi ọkụ na ebe a gbazere ọdọ mmiri (mkpọda ọkụ na ala ọkụ). Na usoro nke ferroalloy agbaze, akụkụ dị iche iche nke refractories dị iche iche na-arụ ọrụ ọnọdụ.

Ọkụ n’elu refractory ihe na-emetụta tumadi site na mbuze na mmetụta nke elu okpomọkụ ọkụ gas na sprayed slag, okpomọkụ mgbanwe n’etiti nri etiti oge na radiant okpomọkụ nke elu-okpomọkụ arc, mmetụta nke airflow na nrụgide mgbanwe n’oge ihe ọdịda.

Igwe ọkụ mgbidi refractories na-ebukarị mmetụta radieshon dị elu nke arc na mgbanwe okpomọkụ n’oge oge nchaji; mmebi na mmetụta nke ọkụ ọkụ ọkụ dị elu gas na slag sprayed; mmetụta na abrasion nke ihe siri ike na ihe ndị na-acha uhie uhie; oké slag corrosion na corrosion nso slag akara Mmetụta nke slag. Na mgbakwunye, mgbe ahụ ọkụ ahụ na-atụgharị, ọ na-enwekwa nrụgide ọzọ.

Mkpọda ọkụ na ala refractories tumadi na-ebu nrụgide nke elu oyi akwa nke ụgwọ ma ọ bụ a wụrụ awụ ígwè; mmetụta nke mgbanwe okpomọkụ, mmetụta ụgwọ na arc agbaze ọnwụ n’oge oge chaja; nbibi na mmetụta nke elu okpomọkụ a wụrụ awụ na slag a wụrụ awụ.

Iji hụ na ọkụ ọkụ eletrik nwere ike ịrụ ọrụ nke ọma, ọ dị mkpa ịhọrọ ihe ndị na-emegharị emegharị na nnukwu refractoriness na ibu dị nro okpomọkụ, ezigbo iguzogide oyi ngwa ngwa na okpomọkụ na nkwụsị nke slag, nnukwu ikike okpomọkụ na ụfọdụ ihe ọkụ ọkụ iji wuo ọkụ eletrik. mkpuchi.

Arụmọrụ na njirimara ojiji nke refractories lining oven nke a na-ejikarị na-emepụta ferroalloys bụ ndị a.

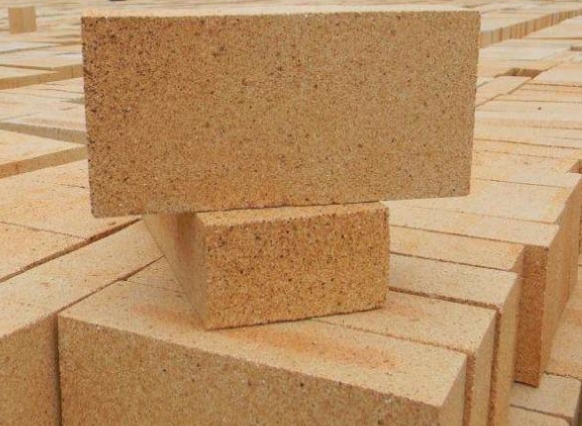

1. brik ụrọ

Isi ihe eji eme brik ụrọ bụ ụrọ na-emegharị ahụ nke nwere ezigbo plasticity na adhesion.

Isi njirimara arụmọrụ nke brik ụrọ bụ: iguzogide siri ike na slag acid, ezigbo nguzogide ngwa ngwa oyi na okpomọkụ, ezigbo nchekwa ọkụ na ụfọdụ ihe mkpuchi; obere refractoriness na ibu nro okpomọkụ. E kwesịghị iji brik ụrọ mee ihe ozugbo n’okpuru ọnọdụ okpomọkụ dị elu na ihe pụrụ iche chọrọ.

Na mmepụta nke ferroalloys, a na-eji brik ụrọ eme ihe maka ịtọ mgbidi ọkụ na mkpuchi nke akụkụ ndị ekpughere nke ọkụ arc na-ekpuchi mmiri, mgbidi ọkụ na ọkụ ọkụ dị n’okpuru ala maka ichekwa okpomọkụ na mkpuchi, ma ọ bụ maka ịtọ akwa ladle.

2. brik alumina dị elu

Isi ihe eji eme brik alumina dị elu bụ alumina bauxite dị elu, na ihe nkedo bụ ụrọ na-atụgharị.

E jiri ya tụnyere brik ụrọ, nnukwu uru nke brik alumina dị elu bụ nnukwu refractoriness, ogo ịdị nro dị elu, ezigbo nguzogide slag na ike ọrụ dị elu. Ihe ọghọm bụ na brik alumina dị elu na-adịghị mma na-eguzogide ngwa ngwa na kpo oku.

N’ime mmepụta nke ferroalloys, a pụrụ iji brik dị elu nke alumina rụọ brik dị n’ime mmiri arc oven na-ekpuchi brik, na-edozi elu ọkụ ọkụ eletrik, a pụkwara iji ya rụọ ihe mkpuchi ígwè a wụrụ awụ.

3. Magnesia brik na magnesia

Isi ihe eji eme brik magnesia bụ magnesite, ihe nkedo bụ mmiri na brine ma ọ bụ sulfite pulp na-emebi mmiri.

Isi njirimara arụmọrụ nke brik magnesia bụ: nnukwu refractoriness na nguzogide dị mma na slag alkaline; ma thermal conductivity na eletriki conductivity na elu okpomọkụ dị ukwuu, na ibu nro okpomọkụ dị ala, na ngwa ngwa jụrụ oyi na kpo oku adịghị mma. Pulverization na-eme mgbe ekpughere ya na mmiri ma ọ bụ uzuoku na oke okpomọkụ.

N’ime mmepụta nke ferroalloys, a na-eji brik magnesia na-ewu ọkụ ọkụ eletrik dị elu nke carbon ferrochrome, ndị na-atụgharị ihe na-emepụta ihe na-eme ka ọkụ eletrik na-eme ka mgbidi ọkụ ọkụ, ọkụ ọkụ, na ladle metal na-ekpo ọkụ nwere ferrochrome na ọkara-obere carbon ferromanganese. Lining wdg Jiri brik magnesia alumina kama brik magnesia iji wuo ụlọ ọkụ. Magnesia nwere nnukwu refractoriness. Na mmepụta nke ferroalloys, a na-ejikarị magnesia eme ihe maka ịkụnye ala ọkụ ọkụ, na-eme ma na-arụzi mgbidi ọkụ na ọkụ ọkụ, na dị ka ihe maka ịkwanye oghere ma ọ bụ na-eme ka ọkpụkpụ na-emepụta ihe.

4. Unyi brik

Ihe ndị bụ́ isi e ji emepụta brik carbon bụ coke na anthracite e gwepịara egwepịa, ihe e ji ejikọta ya bụ coal tar ma ọ bụ pitch.

N’iji ya na ihe ndị ọzọ na-emegharị ihe, brik carbon ọ bụghị naanị nwere ike mkpakọ dị elu, ọnụ ọgụgụ mgbasawanye nke okpomọkụ dị ala, nkwụsị nke ọma, nnukwu refractoriness na ibu dị nro okpomọkụ, ezigbo iguzogide oyi na okpomọkụ, na karịsịa mma slag. Ya mere, enwere ike iji brik carbon dị ka ihe mkpuchi maka ọkụ ọkụ arc maka ụdị ferroalloys ọ bụla nke na-adịghị atụ egwu carburization.

Otú ọ dị, brik carbon dị nnọọ mfe oxidize n’okpuru ọnọdụ okpomọkụ dị elu, na conductivity ha thermal conductivity na electric conductivity dịtụ ukwuu. Na mmepụta nke ferroalloys, a na-ejikarị brik carbon rụọ mgbidi na ala nke ọkụ arc na-emikpu nke na-adịghị ekpuchi ikuku.