- 28

- Nov

What are the refractory bricks commonly used in ferroalloy electric furnaces

What are the refractory bricks commonly used in ferroalloy electric furnaces

Ferroalloy electric furnace refractories include three parts: furnace roof refractories, furnace wall refractories and molten pool refractories (furnace slope and furnace bottom). In the process of ferroalloy smelting, different parts of refractories are in different working conditions.

Furnace top refractory materials are mainly affected by the erosion and impact of high-temperature furnace gas and sprayed slag, the temperature changes between feeding intervals and the radiant heat of high-temperature arc, the impact of airflow and pressure changes during material collapse.

Furnace wall refractories mainly bear the high-temperature radiation effect of the arc and the temperature changes during the charging interval; the erosion and impact of high-temperature furnace gas and sprayed slag; the impact and abrasion of solid materials and semi-molten materials; severe slag corrosion and corrosion near the slag line Impact of slag. In addition, when the furnace body tilts, it also bears additional pressure.

The furnace slope and bottom refractories mainly bear the pressure of the upper layer of charge or molten iron; the effect of temperature changes, charge impact and arc melting loss during the charging interval; the erosion and impact of high temperature molten iron and molten slag.

In order to ensure that the electric furnace can work normally, it is necessary to choose refractory materials with high refractoriness and load softening temperature, good resistance to rapid cold and heat and slag resistance, large heat capacity and certain thermal conductivity to build the electric furnace lining.

The performance and use characteristics of furnace lining refractories often used in the production of ferroalloys are as follows.

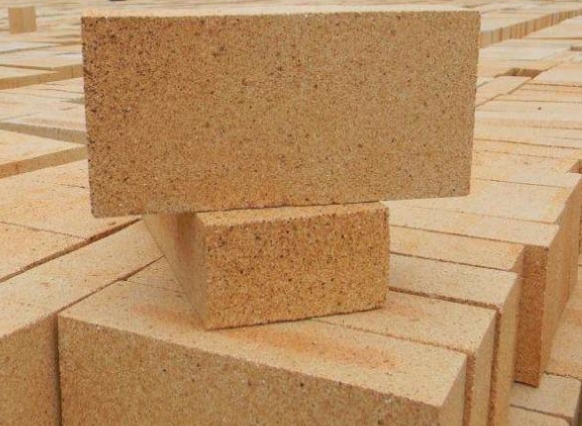

1. Clay bricks

The main raw material for making clay bricks is refractory clay with good plasticity and adhesion.

The main performance characteristics of clay bricks are: strong resistance to acid slag, good resistance to rapid cold and heat, good heat preservation and certain insulation properties; low refractoriness and load softening temperature. Clay bricks should not be used directly under high temperature conditions and special requirements.

In the production of ferroalloys, clay bricks are mainly used for laying furnace walls and linings of exposed parts of submerged arc furnaces, furnace walls and furnace bottom outer linings for heat preservation and insulation, or for laying ladle linings.

2. High alumina brick

The main raw material for making high alumina bricks is high alumina bauxite, and the binder is refractory clay.

Compared with clay bricks, the biggest advantages of high alumina bricks are high refractoriness, high load softening degree, good slag resistance and high mechanical strength. The disadvantage is that the high-alumina bricks have poor resistance to rapid cooling and heating.

In the production of ferroalloys, high-alumina bricks can be used to build submerged arc furnace taphole lining bricks, refining the top of electric furnaces, and can also be used to build molten iron lining linings.

3. Magnesia brick and magnesia

The main raw material for making magnesia bricks is magnesite, and the binder is water and brine or sulfite pulp waste liquid.

The main performance characteristics of magnesia bricks are: high refractoriness and excellent resistance to alkaline slag; but the thermal conductivity and electrical conductivity at high temperatures are large, and the load softening temperature is low, and the rapid cooling and heating resistance is poor. Pulverization occurs when exposed to water or steam at high temperatures.

In the production of ferroalloys, magnesia bricks are used to build high-carbon ferrochrome reduction electric furnaces, medium and low-carbon ferrochrome converters, shakers and refining electric furnace walls, furnace bottoms, and hot metal ladle containing ferrochrome and medium-low carbon ferromanganese Lining etc. Use magnesia alumina bricks instead of magnesia bricks to build the furnace roof. Magnesia has a high refractoriness. In the production of ferroalloys, magnesia is often used for knotting furnace bottoms, making and repairing furnace walls and furnace bottoms, and as a material for plugging holes or making knotted ingot molds.

4. Charcoal bricks

The main raw materials for making carbon bricks are crushed coke and anthracite, and the binder is coal tar or pitch.

Compared with other common refractory materials, carbon bricks not only have high compressive strength, low thermal expansion coefficient, good wear resistance, high refractoriness and load softening temperature, good resistance to rapid cold and heat, and particularly good slag resistance. Therefore, carbon bricks can be used as lining materials for submerged arc furnaces for all types of ferroalloys that are not afraid of carburization.

However, carbon bricks are very easy to oxidize under high temperature conditions, and their thermal conductivity and electrical conductivity are relatively large. In the production of ferroalloys, carbon bricks are mainly used to build the walls and bottoms of submerged arc furnaces that are not exposed to air.