- 28

- Nov

Ziziphi izitena eziphikisayo ezisetyenziswa rhoqo kwiifenethi zombane ze-ferroalloy

Ziziphi izitena eziphikisayo ezisetyenziswa rhoqo kwiifenethi zombane ze-ferroalloy

Iirefractories zeFerroalloy electric furnace zibandakanya iinxalenye ezintathu: iirefractories zophahla lwesithando somlilo, iirefractories zodonga lwesithando somlilo kunye neerefractories zamachibi atyhidiweyo (i-slope yesithando somlilo kunye nomzantsi wesithando somlilo). Kwinkqubo yokunyibilikisa i-ferroalloy, iindawo ezahlukeneyo zokuchasa zikwimeko ezahlukeneyo zokusebenza.

Izixhobo ezichasene ne-furnace top refractory zichaphazeleka kakhulu kukukhukuliseka kunye nefuthe legesi yobushushu obuphezulu kunye ne-slag etshiziweyo, utshintsho lobushushu phakathi kwamaxesha okutya kunye nobushushu obukhazimlayo be-arc yobushushu obuphezulu, impembelelo yokuhamba komoya kunye nokutshintsha koxinzelelo ngexesha lokuwa kwezinto.

I-refractories yodonga lwesithando somlilo ikakhulu ithwala impembelelo ye-radiation ephezulu ye-arc kunye nokutshintsha kweqondo lokushisa ngexesha lokutshaja; ukhukuliseko kunye nefuthe legesi yobushushu obuphezulu kunye ne-slag etshisiweyo; impembelelo kunye ne-abrasion yezinto eziqinileyo kunye ne-semi-molt; i-slag corrosion enzima kunye ne-corrosion kufuphi nomgca we-slag Impembelelo ye-slag. Ukongeza, xa umzimba wesithando somlilo uthambeka, uphinda uthwale uxinzelelo olongezelelweyo.

I-slope yesithando somlilo kunye ne-refractories ephantsi kakhulu ithwala uxinzelelo lomgangatho ophezulu wentlawulo okanye isinyithi esinyibilikisiweyo; impembelelo yokutshintsha kweqondo lokushisa, impembelelo yentlawulo kunye nelahleko yokunyibilika kwe-arc ngexesha lekhefu lokutshaja; ukhukuliseko kunye nefuthe lobushushu obuphezulu bentsimbi enyibilikisiweyo kunye ne-slag etyhidiweyo.

Ukuze kuqinisekiswe ukuba iziko lombane liyakwazi ukusebenza ngokuqhelekileyo, kuyimfuneko ukukhetha izinto eziphikisayo kunye ne-refractoriness ephezulu kunye nobushushu bokuthambisa umthwalo, ukuchasana kakuhle nokubanda ngokukhawuleza kunye nobushushu kunye nokumelana ne-slag, umthamo omkhulu wokushisa kunye nokuhamba kwe-thermal ethile yokwakha iziko lombane. umgca.

Ukusebenza kunye nokusetyenziswa kweempawu ze-furnace lining refractories ezihlala zisetyenziselwa ukuveliswa kwee-ferroalloys zilandelayo.

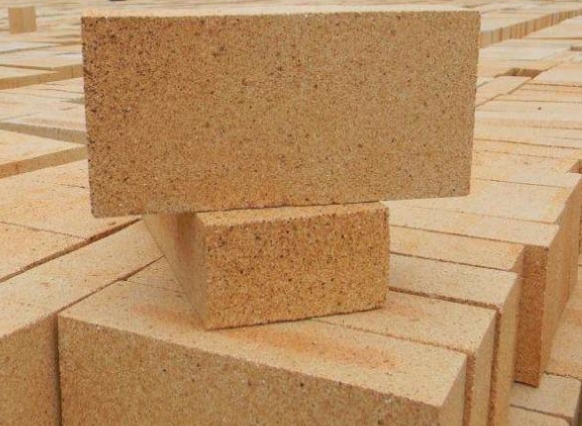

1. Izitena zodongwe

Eyona nto iphambili ekrwada yokwenza izitena zodongwe ludongwe oluphikisayo kunye neplastiki elungileyo kunye nokubambelela.

Iimpawu eziphambili zentsebenzo yezitena zodongwe zezi: ukuchasana okunamandla kwi-asidi slag, ukuchasana kakuhle nokubanda ngokukhawuleza kunye nokushisa, ukugcinwa kakuhle kobushushu kunye neempawu ezithile zokugquma; i-refractoriness ephantsi kunye nobushushu bokuthambisa umthwalo. Izitena zodongwe akufanele zisetyenziswe ngokuthe ngqo phantsi kweemeko eziphezulu zokushisa kunye neemfuno ezikhethekileyo.

Kwimveliso ye-ferroalloys, izitena zodongwe zisetyenziselwa ukubeka iindonga zesithando somlilo kunye ne-linings yeendawo eziveziweyo ze-arc eziphantsi kwamanzi, iindonga zesithando somlilo kunye ne-furnace yangaphandle ye-outer linings yokugcina ubushushu kunye nokugquma, okanye ukubeka i-ladle linings.

2. Izitena eziphezulu ze-alumina

Eyona nto ingundoqo yokwenza izitena ze-alumina ephezulu yi-alumina bauxite ephezulu, kwaye i-binder yi-refractory dongwe.

Xa kuthelekiswa nezitena zodongwe, ezona nzuzo zinkulu zezitena ze-alumina eziphakamileyo zi-refractoriness ephezulu, iqondo eliphezulu lokuthambisa umthwalo, ukuxhathisa okulungileyo kwe-slag kunye namandla aphezulu omatshini. Ukungalungi kukuba izitena eziphezulu ze-alumina zinokumelana okungahambi kakuhle ukupholisa ngokukhawuleza kunye nokufudumala.

Kwimveliso ye-ferroalloys, izitena eziphezulu ze-alumina zingasetyenziselwa ukwakha i-arc furnace taphole lining lining izitena, ukucokisa umphezulu wezitena zombane, kwaye zingasetyenziselwa ukwakha iileyile ezityhidiweyo zentsimbi.

3. Isitena seMagnesia kunye ne-magnesia

Eyona nto ingundoqo yokwenza izitena ze-magnesia yi-magnesite, kwaye i-binder ngamanzi kunye ne-brine okanye i-sulfite pulp waste liquid.

Iimpawu eziphambili zokusebenza kwezitena ze-magnesia zezi: ukuchasa okuphezulu kunye nokuchasana okugqwesileyo kwi-alkaline slag; kodwa i-thermal conductivity kunye ne-conductivity yombane kumaqondo aphezulu aphezulu, kwaye iqondo lokushisa lokunciphisa umthwalo liphantsi, kwaye ukupholisa ngokukhawuleza kunye nokumelana nokufudumeza akubi. I-Pulverization yenzeke xa ibekwe emanzini okanye kumphunga kumaqondo obushushu aphezulu.

Kwimveliso ye-ferroalloys, izitena ze-magnesia zisetyenziselwa ukwakha iziko zombane zokunciphisa i-carbon ferrochrome ephezulu, iziguquli ze-ferrochrome eziphakathi kunye ne-low-carbon ferrochrome, ii-shaker kunye nokucoca iindonga zesithando sombane, i-firnace bottoms, kunye ne-ladle yesinyithi eshushu equkethe i-ferrochrome kunye ne-carbon ferromanganese ephakathi. Ukwalathisa njl. Sebenzisa izitena zemagnesia alumina endaweni yezitena zemagnesia ukwakha uphahla lweziko. I-Magnesia ine-refractoriness ephezulu. Kwimveliso ye-ferroalloys, i-magnesia isoloko isetyenziselwa ukubopha i-knotting bottoms yesithando somlilo, ukwenza kunye nokulungisa iindonga zesithando somlilo kunye nezantsi kwesithando somlilo, kwaye njengento yokufaka imingxuma okanye ukwenza i-knotted ingot molds.

4. Izitena zamalahle

Izixhobo eziphambili zokwenza izitena zekhabhoni zityunyuziwe i-coke kunye ne-anthracite, kwaye i-binder yi-tar yamalahle okanye i-pitch.

Xa kuthelekiswa nezinye izinto eziqhelekileyo ezixhathisayo, izitena zekhabhoni azinayo nje amandla aphezulu okucinezela, i-coefficient ephantsi yokwandiswa kwe-thermal, ukumelana nokunxiba kakuhle, ukuchasana okuphezulu kunye nobushushu bokuthambisa umthwalo, ukumelana kakuhle nokubanda ngokukhawuleza kunye nobushushu, kwaye ngokukodwa ukuxhathisa okuhle kwe-slag. Ngoko ke, izitena zekhabhoni zingasetyenziselwa njengezinto zokugqoka kwii-arc eziphantsi kwamanzi kuzo zonke iintlobo ze-ferroalloys ezingoyikiyo i-carburization.

Nangona kunjalo, izitena zekhabhoni zilula kakhulu kwi-oxidize phantsi kweemeko eziphezulu zeqondo lokushisa, kwaye ukuqhutyelwa kwe-thermal kunye nokuhanjiswa kombane kukhulu. Kwimveliso ye-ferroalloys, izitena zekhabhoni zisetyenziselwa kakhulu ukwakha iindonga kunye neezantsi ze-arc furnaces ezingaphantsi kwamanzi ezingabonakali emoyeni.