- 28

- Nov

Ndezvipi zvidhinha zvinoramba zvinowanzoshandiswa mumagetsi emagetsi eferroalloy

Ndezvipi zvidhinha zvinoramba zvinowanzoshandiswa mumagetsi emagetsi eferroalloy

Ferroalloy electric furnace refractories zvinosanganisira zvikamu zvitatu: choto denga refractories, choto madziro refractories uye yakanyungudutswa dziva refractories (choto mutserendende uye muchoto pasi). Mukuita kwe ferroalloy smelting, zvikamu zvakasiyana zve refractories zviri mumamiriro akasiyana ekushanda.

Furnace yepamusoro refractory zvinhu zvinonyanya kukanganiswa nekukukurwa uye kukanganisa kweyepamusoro-tembiricha yechoto gasi uye yakapfapfaidzwa slag, tembiricha inoshanduka pakati penguva dzekudyisa uye kupisa kunopenya kwearc-tembiricha arc, kukanganisa kwekuyerera kwemhepo uye kudzvanywa kwekuchinja panguva yekudonha kwezvinhu.

Furnace wall refractories inonyanya kutakura yakanyanya-tembiricha radiation mhedzisiro yearc uye tembiricha inoshanduka panguva yekuchaja nguva; kukukurwa uye kukanganisa kwegasi rechoto chemoto uye kupfapfaidza slag; kukanganisa uye kuputika kwezvinhu zvakasimba uye semi-yakanyungudutswa zvinhu; yakanyanya slag corrosion uye corrosion pedyo neslag line Impact ye slag. Mukuwedzera, kana muviri wechoto unorereka, unotakurawo kuwedzera kumanikidza.

Kutsetseka kwechoto uye pasi refractories inonyanya kutakura kumanikidzwa kwepamusoro pechaji kana simbi yakanyungudutswa; Mhedzisiro yekuchinja kwekushisa, kukanganisa kwechaji uye arc kunyungudika kurasikirwa panguva yekuchaja nguva; kukukurwa uye kukanganisa kwekushisa kwakanyanya kwesimbi yakanyungudutswa uye slag yakanyungudutswa.

Kuti uve nechokwadi chekuti choto chemagetsi chinogona kushanda zvakajairwa, zvinodikanwa kuti usarudze zvigadziriso zvine refractoriness yakakwira uye tembiricha yekunyorovesa mutoro, kumira zvakanaka kukurumidza kutonhora uye kupisa uye kuramba kweslag, hombe yekupisa uye kumwe kupisa kwemoto kuvaka choto chemagetsi. lining.

Kuita uye kushandiswa kwemaitiro echoto lining refractories anowanzoshandiswa mukugadzirwa kweferroalloys ndeaya anotevera.

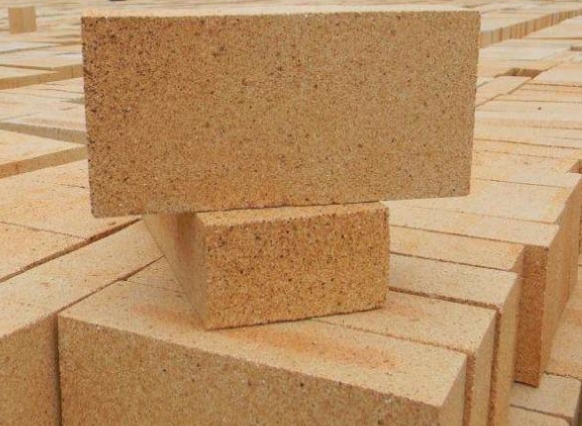

1. Zvidhinha zvevhu

Iyo huru mbishi yekugadzira zvidhinha zvevhu ivhu refractory rine yakanaka plasticity uye adhesion.

Hukuru hwekuita maitiro ezvidhinha zvevhu ndeiyi: kupikisa kwakasimba kune acid slag, kupikisa kwakanaka kukurumidza kutonhora nekupisa, kuchengetedza kwakanaka kwekupisa uye zvimwe zvekudzivirira; low refractoriness uye mutoro softening tembiricha. Zvidhinha zvevhu hazvifanirwe kushandiswa zvakananga pasi pemamiriro ekushisa kwakanyanya uye zvinodiwa zvakakosha.

Mukugadzira ferroalloys, zvidhinha zvevhu zvinonyanya kushandiswa kuisa madziro echoto uye maratanirwo enzvimbo dzakavhurika dzearc furnaces, madziro echoto uye muchoto wepasi machira ekunze ekuchengetedza kupisa uye kuvhara, kana kuisa ladle linings.

2. High alumina brick

Chinhu chikuru chekugadzira zvidhinha zvealuminium yakakwira yakakwira alumina bauxite, uye binder ivhu rinoramba.

Kuenzaniswa nezvidhinha zvevhu, mabhenefiti makuru ealumina akakwira zvidhinha ndeyerefractoriness, yakakwira yekunyorovesa dhigirii, yakanaka slag kuramba uye yakakwirira mechani simba. Izvo zvisingabatsiri ndezvokuti zvidhinha zvepamusoro-aluminium zvine hutsika husina kupikisa kukurumidza kutonhora uye kupisa.

Mukugadzirwa kweferroalloys, zvidhinha zvepamusoro-aluminium zvinogona kushandiswa kuvaka yakanyungudutswa arc furnace taphole lining zvidhinha, kunatsa pamusoro pemavira emagetsi, uye zvakare inogona kushandiswa kuvaka yakanyungudutswa yesimbi lining lining.

3. Magnesia zvidhinha uye magnesia

Chinhu chikuru chekugadzira magnesia zvidhinha magnesite, uye binder imvura uye brine kana sulfite pulp tsvina yemvura.

Hukuru hwekuita maitiro e magnesia zvidhinha ndezvi: high refractoriness uye kupikisa kwakanyanya kune alkaline slag; asi thermal conductivity uye magetsi conductivity panguva yakakwirira tembiricha yakakura, uye mutoro softening tembiricha yakaderera, uye kukurumidza kutonhora uye kudziyisa kuramba murombo. Pulverization inoitika kana yaiswa mumvura kana mupfunga patembiricha yakakwira.

Mukugadzira ferroalloys, magnesia zvidhinha anoshandiswa kuvaka high-carbon ferrochrome kuderedza mabira emagetsi, yepakati uye yakaderera-kabhoni ferrochrome converters, shaker uye kunatsa magetsi echoto madziro, echoto bottoms, uye inopisa simbi ladle ine ferrochrome uye yepakati-yakaderera kabhoni ferromanganese. Lining etc. Shandisa magnesia alumina zvidhinha pane magnesia zvidhinha kuvaka denga rechoto. Magnesia ane high refractoriness. Mukugadzira ferroalloys, magnesia inowanzoshandiswa kupfumbura mbambo dzechoto, kugadzira uye kugadzirisa madziro echoto uye mbiru dzechoto, uye sechinhu chekuvhara maburi kana kugadzira mapfumo engot molds.

4. Zvidhinha zvemarasha

Zvinhu zvikuru zvekugadzira zvidhinha zvekabhoni zvakapwanyika coke uye anthracite, uye binder itara yemarasha kana pitch.

Zvichienzaniswa nezvimwe zvinozivikanwa zvinoramba zvichiitwa, zvidhinha zvekabhoni hazvina simba rakawanda rekumanikidza, kuderera kwekuwedzera kwemafuta ekuwedzera, kushomeka kwekusagadzikana, kukwirira kwepamusoro uye tembiricha yekunyorovesa mutoro, kurwisa kutonhora nekukurumidza uye kupisa, uye kunyanya kunaka kwe slag kuramba. Naizvozvo, zvidhinha zvekabhoni zvinogona kushandiswa semidziyo yekumisikidza kune yakanyura arc furnaces kune ese marudzi eferroalloys asingatyi carburization.

Nekudaro, zvidhinha zvekabhoni zviri nyore kwazvo kuita oxidize pasi pemamiriro ekushisa kwakanyanya, uye yavo yekupisa conductivity uye magetsi conductivity yakakura. Mukugadzirwa kweferroalloys, zvidhinha zvekabhoni zvinonyanya kushandiswa kuvaka madziro uye mabheti emvura yakadzika yearc furnaces isingaonekwi nemhepo.