- 13

- Sep

Kev hloov pauv los ntawm tshuaj lom neeg hlau mus rau steelmaking los ntawm kev siv cua-permeable cib nruab nrab

Kev hloov pauv los ntawm tshuaj lom neeg hlau mus rau steelmaking los ntawm kev siv cua-permeable cib nruab nrab nruab nrab zaus rauv tshuab hluav taws xob

Lub tshuab ua kom sov nruab nrab nruab nrab nruab nrab thev naus laus zis tau hloov pauv qhov zoo tib yam induction melting rauv los ntawm cov tshuaj lom neeg hlau rau steelmaking. Muaj ntau zaus, qhov zoo ntawm cov hlau yaj (hlau) tau mus txog qib kev ua kom zoo dua qub ntawm AOD rauv, LF ua kom lub tshuab ua kom sov, thiab VD lub tshuab nqus tsev rauv.

Qhov zoo ntawm kev siv roj diffuser:

1. Txhawb kev ntab ntawm kev suav nrog hauv cov hlau yaj, txo qhov suav nrog, thiab txhim kho qhov zoo ntawm cov hlau yaj;

2. Txhim kho kev siv cov tshuaj ntxiv;

3. Txo cov seem seem;

4. Ntev lub neej ntawm cov cua sov hauv ob sab phlu;

5. Kev nqis peev qis;

6. Muab lub tshuab rhaub hluav taws xob ua kom rov ua haujlwm zoo los muab kev txhawb zog rau kev txhim kho cov hlau yaj thiab ua cov khoom tshiab.

, Yuav ua li cas rau nruab cov pa diffuser

1.1 Kev npaj ua ntej kev teeb tsa

1) Ua haujlwm ¢ 18mm puag ncig lub qhov nyob hauv nruab nrab ntawm hauv qab ntawm lub qhov cub hluav taws xob hluav taws xob (ib feem ntawm lub cub tawg zoo tau tshwj tseg) los pab txhawb kev teeb tsa cov raj xa hluav taws xob.

2) Txhuam H-ntug xim ntawm cov kauj induction thiab siv cov ntawv txhuam. Qee lub qhov cub tseem tab tom tso cov paib mica thiab ntaub asbestos rau ntawm phab ntsa sab hauv ntawm cov ntawv txhuam.

3) Npaj cov raj hlau nrog phab ntsa tuab ntawm 1 ~ 2mm, txoj kab uas hla ntawm 200 ~ 350mm raws li qhov cub tawg, thiab qhov siab ntawm 250 ~ 300mm. Sab nrauv yog tiaj thiab huv. Txhawm rau tshem tawm tau yooj yim, ob leeg tuaj yeem txuas tau.

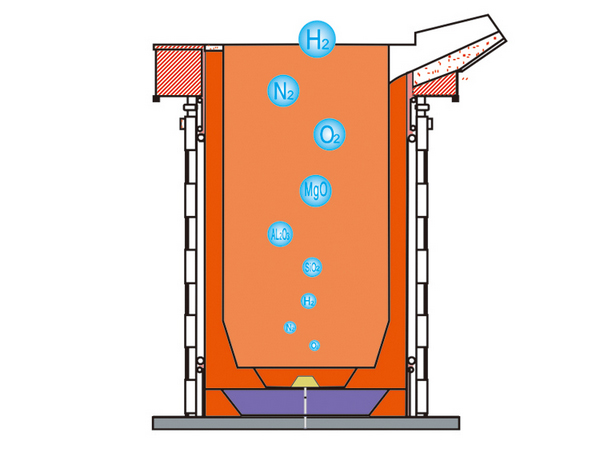

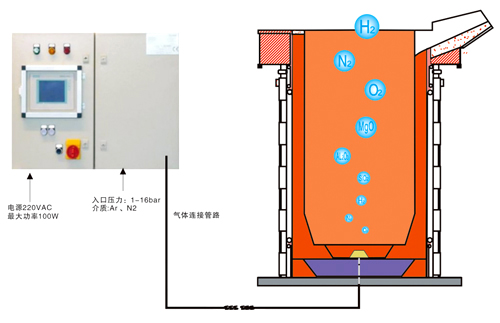

4) Npaj cov pa roj, xws li lub raj mis argon, nitrogen, thiab lwm yam. Thaum cov roj ntim loj, ntau lub tog raj kheej roj tuaj yeem tsim ua lub busbar; lub ntsuas cua siab txuas nrog lub qhov hluav taws xob ntawm qhov chaw tso pa (thaj tsam 99.99 ~ 0Mpa), lub ntsuas ntsuas dej (thaj tsam 2 ~ 0L/min), rab koob valve (piv rau tswj cov pa ntws); hauv kev tsim cov khoom lag luam loj, koj tuaj yeem teeb tsa “ntse tswj cov pa roj” (muab los ntawm lub tuam txhab), kom cov roj tuaj yeem siab, txawj ntse, Txhim kho kev tswj hwm (saib cov tuam txhab cov khoom lag luam lossis lub vev xaib kom paub meej).

1.2 Txhim kho cov pa roj diffuser

Tom qab cov kev npaj saum toj no tau ua tiav, hla lub raj xa hluav taws xob rov qab lub raj (lub raj rov qab ntawm lub diffuser yog xov sab nraud, M16 × 2mm) dhau los ntawm lub qhov puag ncig hauv qab, kho nws hauv qab ntawm lub qhov cub tawg nrog cov txiv ntoo thiab gasket, thiab ua rau sab saum toj ntawm cov pa roj diffuser Qhov siab yog li 100 hli qis dua sab saud ntawm cov khoom siv hauv qab ntawm lub qhov cub tawg (raws li qhia hauv daim duab), thiab qhov siab ntawm sab saud ntawm cov pa diffuser qis dua ntau dua lossis sib npaug rau qhov siab ntawm lub nplhaib hauv qab ntawm cov kauj induction. Txuas tus adapter (lub taub hau Pagoda) mus rau lub raj tom qab ntawm lub diffuser, thiab tom qab ntawd txuas nws mus rau lub tog raj kheej roj; koj tseem tuaj yeem txuas ncaj qha cov hlau txuas mus rau lub raj tsheb tom qab ntawm cov pa roj sib cais kom ntseeg tau tias lub raj xa dej sib txuas sib txuas tsis xau (raws li qhia hauv daim duab). Tsis txhob xyuam xim: thaum txheej txheem kev sib txuas, tsis muaj khib nyiab, hmoov av, thiab lwm yam yuav tsum poob rau hauv cov raj xa dej.

Tom qab ntawd, npog cov pa roj diffuser nrog lub raj hlau npaj ua ntej, ntsuas qhov chaw ntawm cov raj hlau, tso lub diffuser nyob hauv nruab nrab ntawm cov raj hlau, ncuav cov khoom qhuav qhuav rau sab nraum cov raj hlau, thiab tom qab ntawd ua raws induction cua sov qhuav cov khoom siv vibrating txheej txheem Sab nrauv ntawm cov raj hlau nruas raug ntaus nrog cov khoom siv vibrating qhuav kom ua kom nws nruj thiab ua raws li qhov siab ntawm cov khoom siv cua sov hauv qab. Tom qab kev co thiab ramming ntawm cov khoom siv vibrating qhuav sab nraum cov raj hlau, maj mam rub cov raj hlau, rhuav tawm cov ntawv nplaum rau ntawm cov pa diffuser, thiab nchuav “cov khoom ua pa” mus rau hauv lub qhov taub nruab nrab ntawm lub cub tawg hauv qab . 100mm, ramming thiab compacting cov khoom ua pa txheej los ntawm txheej, thiab ua kom qhov siab ntawm cov khoom siv ua pa thiab cov cua sov hauv qab qhuav cov khoom vibrating zoo ib yam. Ceev faj tsis txhob ua kom cov pa diffuser puas tsuaj thaum siv rab diav rawg vibrator. Tom qab cov khoom siv tso tawm sab hauv, siv lub diav rawg los txhawm rau kos lub diav rawg sib sib zog nqus nyob ib ncig ntawm 2 rau 3 lub lis piam, thiab ntxig cov lus qhia ntawm rab diav rawg rau hauv qhov sab hauv thiab sab nraud ntawm ib puag ncig tib lub sijhawm. Siv lub tshuab vibrator nruab nrog lub taub hau tiaj kom rov ua dua thiab ram lub diav rawg cim rau ntawm ib puag ncig thiab sab saud ntawm cov khoom siv ua pa kom ua kom tiaj thiab ntsaws cov pa diffuser. Kev teeb tsa cov pa roj diffuser tau ua tiav.

Tom qab ntawd, ua kom tiav cov txheej txheem ua cua sov tom ntej: ua kom cov txheej txheem steel pwm (cov hlau pwm yuav tsum tau ua los ntawm cov hlau phaj nrog tuab ntawm 6mm lossis ntau dua, uas yog qhov ua rau lub sintering ntawm lub qhov cub tawg) → ua raws li induction cua sov qhuav vibrating cov khoom tsim cov txheej txheem txhawm rau txhawm rau lub tshuab ua kom sov phab ntsa thiab cov cua sov phab ntsa Qhov siab ntawm cov khoom qhuav nce mus txog 50 hli los ntawm lub qhov cub tawg, sab saud ntawm cov khoom ntub blasting rauv phab ntsa, cov khoom ntub blasting lub qhov ncauj thiab qhov ncauj. Yog tias cov hlau tsis tuaj yeem rub tawm, nws yuav tsum tau yaj rau hauv cov hlau yaj nrog lub tshuab cua sov hauv ob sab phlu.

2. Lub qhov cub tawg sintering thiab sim tshuab

Lub hauv paus sintering kuj suav nrog kev ua txhaum ntawm “cov khoom ua pa”, uas yog qhov tseem ceeb heev. Qhov ua tau zoo ntawm kev sintering muaj feem cuam tshuam nrog lub neej ntawm cov kab hauv qab thiab kev siv cov pa diffuser.

Cov cua sov rau melting hlau yuav tsum siv cov khoom ntom ntom. Piv txwv li, siv cov seem luv thiab cov khoom zoo kom ntau li ntau tau. Qhov kub nce ntawm tus nqi ntawm 200-300 ° C ib teev mus rau 1100 ° C rau li 1 teev, thiab tom qab ntawd qhov kub nce ntawm tus nqi ntawm 300 ° C/teev. Qhov siab yuav tsum nce siab me ntsis saum cov ntaub ntawv qhuav/ntub khoom sib txuas, thiab khaws nws ntawm 1680 ~ 1700 ℃ rau 1 ~ 2 teev.

Tom qab sintering thiab tuav, koj tuaj yeem sim tshuab.

Maj mam qhib rab koob lub ntsej muag thiab tshuaj xyuas tus kheej thiab kho cov pa ntws kom ntseeg tau tias muaj cov npuas thiab qhov me me ntawm cov nplaim hlau yaj kom tsis txhob ntim cov pa ntau dhau, cov hlau yaj ua kom tawg, thiab nthuav tawm huab cua ua rau muaj oxidation thib ob thiab nkag mus.