- 04

- Dec

Research on the Manufacturing Process of Motor Shell Castings

Research on the Manufacturing Process of Motor Shell Castings

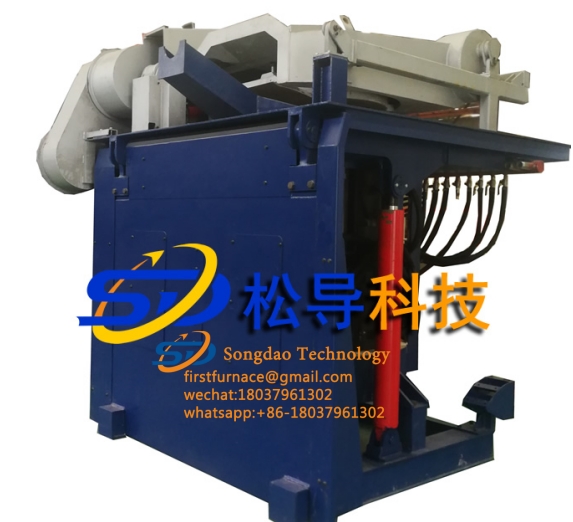

The application of motor shell castings is very common, and the difficulty of its production depends on the structure, size and technical requirements. This motor shell is used in electric locomotives, and the requirements for surface quality and internal quality of castings are relatively high. The molten iron used for pouring the motor shell is an induction melting tanuru.

Process analysis of motor shell castings

The inner cavity of the upper part of the casting is more complicated, with more local protrusions; there are also more heat sinks outside the casting; therefore, there are more “T” and “L” heat nodes in the casting, and it is difficult to feed the casting. Flat cast and cast, the modeling operation is relatively simple, but the feeding of the motor shell casting is very difficult, especially for the protruding part of the upper inner cavity with complex structure, basically there is no way to solve the feeding problem.

Flat or vertical vertical pouring, the riser is set at the upper end, but the casting wall is thick, the lower is thick and the upper is thin, and the casting is taller, the feeding of the lower part is also very difficult. In addition, the deformation of castings is also a problem that needs to be faced.

Analysis and control of the deformation of the motor shell casting

The motor shell casting is not a very complete cylinder. There are many auxiliary structures such as raised straps on the cylinder. The wall thickness of each part of the casting varies greatly, and the stress during the cooling and solidification of the casting will be relatively large. The deformation tendency of the casting is Unable to predict accurately. The initial casting of the motor shell has a difference of 15 mm in the diameter of the end of the straight barrel, which is more elliptical. By setting a ring-shaped casting rib at the end of the straight barrel, the diameter error of the end of the straight barrel is within 1mm.